Posts

Showing posts from 2012

Scientists Produce Hydrogen for Fuel Cells Using an Inexpensive Catalyst Under Real-World Conditions

- Get link

- Other Apps

Self-Charging Power Cell Converts and Stores Energy

- Get link

- Other Apps

Scientists Use Microbes to Make 'Clean' Methane

- Get link

- Other Apps

Clothing the Body Electric: Cotton T-Shirt Fabric Can Store Electricity, Maybe Keep Your Cell Phone Charged

- Get link

- Other Apps

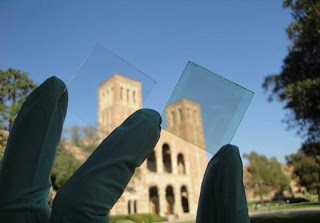

Highly Transparent Solar Cells for Windows That Generate Electricity

- Get link

- Other Apps

ZPlasma: Plasma Startup Creates High-Energy Light to Make Smaller Microchips

- Get link

- Other Apps

The Anatomy Of A Pass, A Quantitative Analysis On Why A VC Passes

- Get link

- Other Apps

Peter Thiel - about cleantech investing

- Get link

- Other Apps

Global Investment in Renewable Energy Powers to Record $257 Billion

- Get link

- Other Apps

Carbon Is Key for Getting Algae to Pump out More Oil

- Get link

- Other Apps

Scientists Generate Electricity from Viruses

- Get link

- Other Apps

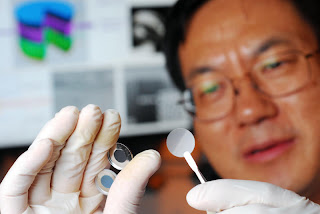

Artificial Leaf Device Produces Hydrogen in Water Using Only Sunlight

- Get link

- Other Apps

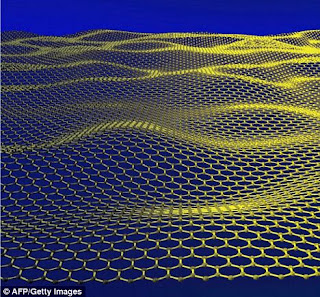

Graphene Boosts Efficiency of Next-Gen Solar Cells

- Get link

- Other Apps

Solar Cell That Also Shines: Luminescent 'LED-Type' Design Breaks Efficiency Record

- Get link

- Other Apps

Nature's Billion-Year-Old Battery Key to Storing Energy

- Get link

- Other Apps

Artificial Photosynthesis Breakthrough: Fast Molecular Catalyzer

- Get link

- Other Apps

Algae Biofuels: The Wave of the Future

- Get link

- Other Apps

Researchers Produce Environmentally Friendly Surfactants Using Biotechnology

- Get link

- Other Apps

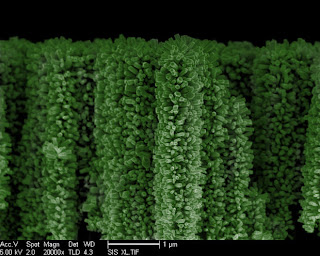

Nanotrees Harvest the Sun's Energy to Turn Water Into Hydrogen Fuel

- Get link

- Other Apps

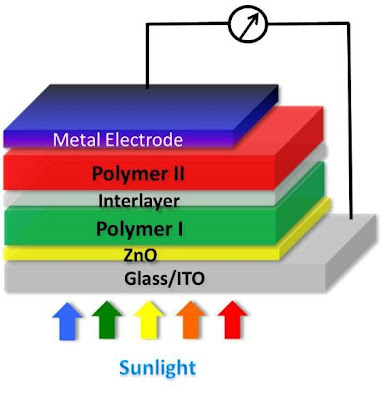

Engineers Create Tandem Polymer Solar Cells That Set Record for Energy-Conversion

- Get link

- Other Apps